Our guide to choosing the vehicle restraints for your loading bays

Home » Our guide to choosing the vehicle restraints for your loading bays

The Kopron vehicle restraints represent a further step in research for safety of vehicles docked at loading bays during loading/unloading operations. These loading bay equipments were conceived to guarantee and reinforce the security of loading sistems and people’s safety by limiting risks of accidents that generally occur during transshipment begins.

Our guide to choosing the vehicle restraints for your loading bays

The 6 major risks during loading and unloading operations

Kopron ensures a ‘turn-key’ service in full observance of an integrated design with the loading bay. The vehicle restraints represent a further step forward for safety of vehicles and people during the loading/unloading operations. Their function is to avoid any accidental movement of the vehicle which would create danger for people handling the goods. The loading dock safety system helps to prevent any danger for the cargo handlers by integrating with the door and the dock leveler.

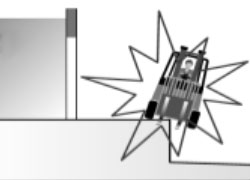

Below, we find out what are the 6 major risks, that might arise in fatal risks, due to the lack of such systems.

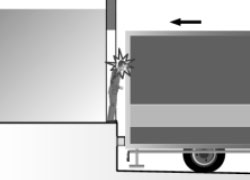

RISKS OF NON-INTEGRATION BETWEEN THE LOADING BAY AND THE VEHICLE RESTRAINT SYSTEM

SOLUTION: The integration between vehicle restraints and loading bays prevents the accidental door opening and/or activation of the dock leveler.

SOLUTION: The integration between vehicle restraints and loading bays prevents the accidental door opening and/or activation of the dock leveler.

SOLUTION: The integration between vehicle restraints and loading bays prevents that the operator leans over from the door to guide the driver’s maneuver.

SOLUTION: The integration between vehicle restraints and loading bays prevents the progressive movement of the lorry or unexpected departure of the truck due to miscommunication.

RISKS OF THE OPERATOR BEING CRUSHED OR GETTING HIT

SOLUTION: The risk of being crushed or getting hit is avoided by easy line guides that maintain the gap between trucks docked at the loading bays. These are installed together with the vehicle restraints.

SOLUTION: The risk of being crushed or getting hit is reduced thanks to vehicle restraints, not requiring the physical presence of an operator to guide the driver’s maneuver. The positioning of the truck at the loading bay is through traffic light and guides.

Main advantages of loading dock safety systems

Thanks to the automatic or manual vehicle restraints, the truck approaching in reverse is totally immobilized. In this way, the forklift driver is allowed to position the dock leveler and loading-unloading operations can be proceed in safety. After that, the bay operator closes the sectional door or barrier and puts the dock leveler in rest position, allowing the lorry to leave.

IMMOBILIZE ALL TYPES OF TRAILERS

The Vehicle restraints guarantee a total immobilization of the truck, reinforcing the security of loading systems and people’s safety. Among various advantages, the Kopron vehicle restrains:

- Are simple and reliable

- Make the operation automatic and safety

- Can be installed in any conditions (new buildings, existing levelers and wheel guides, …)

- Require a simple maintenance

- Movement are synchronised with the loading bay door

Differences between Kopron vehicle restraints

Kopron proposes three models with automatic vehicle restraint system, K-AUTOBLOCK, K1-CALEMATIC and K2-CALEMATIC, and one model with manual vehicle restraint, K-EASYBLOCK.

K-AUTOBLOCK

AUTOMATICEXTERNALINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

AUTOMATICEXTERNALINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

K1-CALEMATIC

2 PARALLEL PITS5 O 6 SINGLE WHEEL CHOCKS FOR EACH PITAUTOMATICINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

2 PARALLEL PITS5 O 6 SINGLE WHEEL CHOCKS FOR EACH PITAUTOMATICINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

K2-CALEMATIC

1 PIT5 O 6 DOUBLE WHEEL CHOCKS FOR EACH PITAUTOMATICINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

1 PIT5 O 6 DOUBLE WHEEL CHOCKS FOR EACH PITAUTOMATICINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

K-EASYBLOCK

MANUALEXTERNALINTEGRATED WITH THE DOCK LEVELER AND THE DOOR

MANUALEXTERNALINTEGRATED WITH THE DOCK LEVELER AND THE DOOR